Description

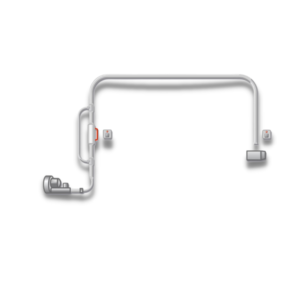

The microprocessor-controlled single or multi-zone system

Key Features

- Graphic monitoring and statistical analysis of all transport operations

- Proven, reliable pneumatic tube system control, which has been continuously developed for over 20 years and is in use worldwide

- The windows-based operating system for a maximum of 254 stations, 128 lines, and 65,000 locations for various pneumatic tube applications and requirements

- Transponder function for automatic carrier transport, carrier counter, and statistical analysis

- Optional touch screen with shortcut keys

- Comprehensive additional functions such as substitution mode, priority control, slow speed for sensitive goods, e-mail signaling, a fire alarm circuit, secured transport

Reviews

There are no reviews yet.